Solutions to Your Broken Cold Chain: How to Prevent and Remediate Temperature Excursions

Global Cold-Chain Situation

In the ever-evolving landscape of global logistics, the cold chain industry has emerged as a key player, witnessing remarkable growth in recent years. Notably, back in 2020, the global cold chain logistics market boasted a substantial value of $202.17 billion. Looking ahead to the forecast for 2030, with a projected market value of $782.27 billion, this sector is set to experience a staggering Compound Annual Growth Rate (CAGR) of 14.6% from 2021 to 2030.

However, this exponential growth doesn’t come without its set of unique challenges. Cold chain logistics face significant obstacles, including the imperative need for substantial infrastructure investments, stringent temperature monitoring requirements, and a critical shortage of skilled labor willing to operate in the bone-chilling environments that this industry demands.

These concerns within this sector are not just industry murmurs; they are supported by the findings of the NTT report. A striking 74% of shippers and a remarkable 91% of third-party logistics providers (3PLs) have expressed their concerns about the increasing competition in this niche. What’s more, a substantial 82% of shippers and 84% of 3PLs firmly believe that the demand for cold chain capacity is poised to surge over the next three years

A peek at India’s cold chain industry

A peek at India’s cold chain industry

In India, the cold chain logistics landscape presents both challenges and opportunities. The country is a major producer of perishable goods, producing a staggering 400 million MT annually. Additionally, India ranks as the world’s largest producer and consumer of dairy products, accounting for over one-fifth of global milk production. Despite these impressive agricultural accomplishments, India’s cold chain infrastructure faces significant limitations.

Approximately 3,500 service providers actively provide transportation and distribution services for the agricultural sector. India currently boasts more than 8,100 cold storage facilities with a combined capacity that exceeds 30 million MT. However, this capacity addresses only a fraction of the nation’s total requirements. It’s noteworthy that 92% of these facilities are under private ownership and operate with an average capacity utilization rate of 75%. Nevertheless, inadequate infrastructure and industry collaboration result in approximately 16% wastage of fruits and vegetables.

Steps

In modern business, precision is primary, and reliability is non-negotiable. Amidst this backdrop, a significant challenge quietly endures: the intricate job of handling products that are sensitive to temperature fluctuations.

Monitoring Temperature and humidity

Monitoring Temperature and humidity

This involves using temperature monitoring devices, such as data loggers or temperature/humidity sensors, to continuously monitor the temperature of your products at each stage of the cold chain. By regularly checking and recording temperature readings, you can quickly identify any deviations from the desired temperature range. This can help and take immediate action to address the issue. This could involve adjusting storage conditions, replacing faulty equipment, or implementing alternative transportation methods. By closely monitoring temperature levels, you can ensure that your temperature-sensitive products remain safe and of high quality throughout the entire cold chain.

Location Tracking for Precision

GPS technology powers these sensors, actively tracking your products’ locations as they progress through the supply chain. This real-time knowledge of your products’ whereabouts ensures that they receive proper storage and transportation conditions. This capability holds particular significance for temperature-sensitive products, as any deviations from the desired temperature range can jeopardize their quality and safety. Additionally, these sensors offer essential data for streamlining your cold chain operations by pinpointing transportation bottlenecks and inefficiencies. By incorporating location tracking sensors, you can rest assured that your products are undergoing proper handling and reaching their destination in optimal condition.

Door open/close sensors for real-time alerts

These sensors can detect door openings and closures, offering valuable information regarding potential temperature excursions. If someone leaves a door open for an extended period, it can cause the storage area’s temperature to deviate from the desired range. These sensors can promptly notify you when a door opens, enabling you to take immediate action to resolve the problem and prevent any damage. By integrating these sensors, you can guarantee that your products consistently experience suitable storage and transportation conditions, reducing the risk of temperature fluctuations and preserving the quality and safety of your cold chain.

Actionable Insights for Proactive Management

This entails implementing systems and technologies that can monitor and track temperature levels throughout the entire supply chain. Real-time data and alerts enable you to promptly detect temperature excursions and take immediate action to prevent damage or spoilage. Furthermore, insightful recommendations, rooted in historical data and industry best practices, assist in proactively addressing potential issues before they manifest. This proactive approach preserves the quality and safety of your temperature-sensitive products and guarantees the success of your cold chain operations.

Vendor Compliance Reports for Reliability

One important tool in preventing and remedying temperature excursions in your cold chain is the use of vendor compliance reports. These reports provide valuable information about the performance and reliability of your suppliers and vendors in maintaining temperature control. Regularly reviewing reports helps identify improvement areas, ensuring cold chain integrity through prompt corrective actions.

Turning Insights into Action

After gathering insights from your vendor compliance reports, you must actively convert those insights into action. This involves taking the necessary steps to address any identified issues or areas for improvement. For instance, if a supplier consistently fails to maintain the required temperature control, you should consider seeking a new supplier. Utilize vendor compliance reports for cold chain integrity and temperature control, averting deviations.

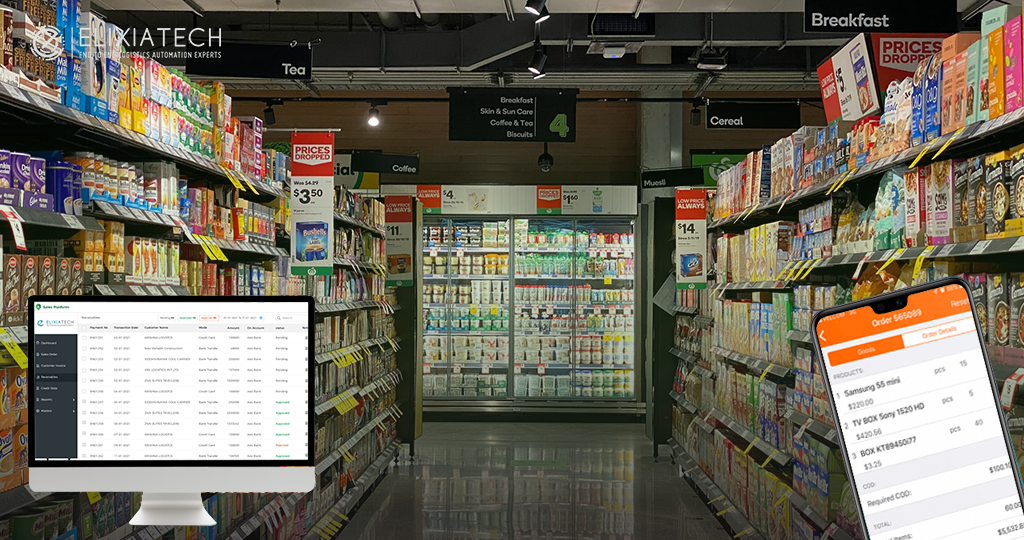

Elixia’s Cold Chain Logistics Solution

A one-stop solution for the problems one faces with cold chain logistics. This product helps in maintaining the quality of perishable/ temperature-sensitive products by:

- monitoring the temperature 24*7 with the web as well as mobile-based solution

- providing real-time alerts in case of any deviations

- tracking humidity and generator set parameters

- maintaining the same temperature across locations and many more.

This relatively economical solution can help in the reduction of daily losses resulting in huge savings for the company annually.

Talk to our experts for customized solutions