Podcast | Episode 8 | Achieve the Net Zero Cold Chain

The global cold chain market size is expected to grow at a whopping CAGR of 18.6% from 2023 to 2030 but are we doing anything to control its carbon footprint?

Check out this Podcast, presented by our Senior Marketing Manager, Dipinder Kaur where she shares a few critical tips to achieve a net zero cold chain.

Cold chain’s carbon footprint contribution

Cold chains are an energy-intensive industry, which deals with the storage, distribution, and transportation of temperature-sensitive products. The cold chain has become a necessity today to ensure we get fresh food and unadulterated chemicals and pharmaceutical products. There are 3 basic reasons for the carbon footprint contribution from the cold Chain (As per Columbia Climate School Report).

1. Cold chain equipment and setup are energy intensive:

The equipment and setup of the cold chain which includes reefer trucks, temperature-controlled warehouses, shipping containers, etc. depend on massive amounts of fuel to keep all the machinery working. Fluorinated gases, which are used as refrigerants, also contribute to global warming.

2. Waste produced due to product loss:

Product wastage due to temperature deviation adds up to carbon emissions from the cold supply chain. Food loss and waste contribute to carbon emissions from the transportation of products and methane emissions due to their disposal. These contribute to nearly 4.4 Gigatons of Co2 emissions each year.

3. Carbon emissions from the cold chain:

Cooling technologies leak powerful greenhouse gases into the atmosphere. Cooling technologies also leak powerful greenhouse gases. The emissions released from these have immense potential for global warming. They are almost 25k times more powerful than carbon dioxide at atmospheric warming.

Listen to this short Podcast to get a brief on the steps to achieve Net Zero Cold Chain.

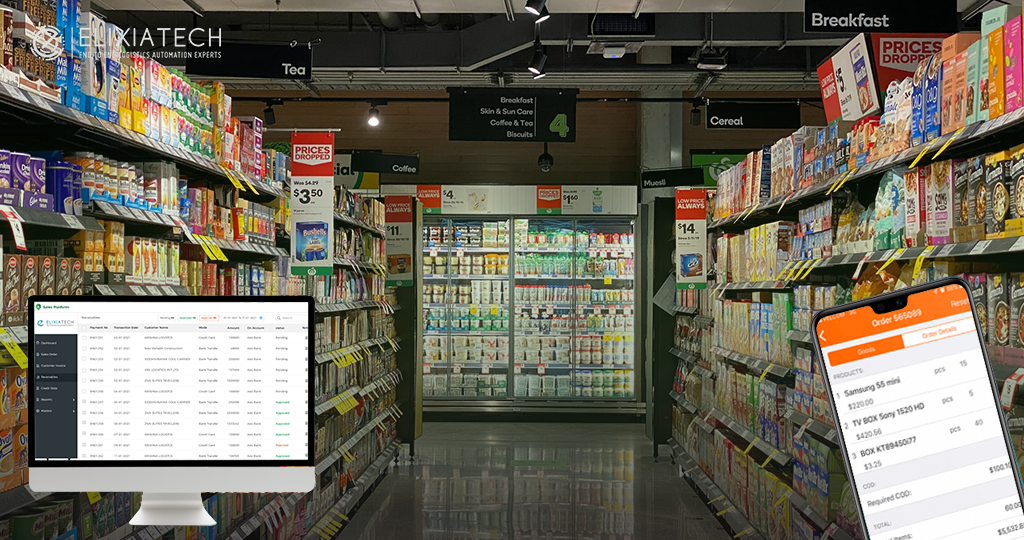

Elixia’s Intelligent Delivery Orchestration Platform is also applicable for cold chain companies. Its wide range of solutions ensures effective storage, transportation, and delivery of temperature-sensitive products. Elixia’s temperature monitoring sensor can be installed in cold storage rooms, warehouses, and reefer trucks to get constant updates on temperature, humidity, and other ambient conditions. It instantly sends out deviation alerts to all relevant stakeholders to initiate immediate corrective actions. Real-time non-compliance reports and also prepared and shared to analyze the performance of the cold chain.One can integrate this module with other modules like tracking, proof of delivery, billing, and even the company’s legacy systems to gain end-to-end visibility and control over the cold chain.

You can also achieve zero emission cold chain!

Talk to us now!

Related Blog Post:

Cold chain logistics: Benefits of Temperature Monitoring!