The transition from Supply Chain 4.0 to Supply Chain 5.0 is the next imminent step in the journey of digital transformation. For years, Supply Chain evolution has run in parallel with Industrial evolutions. In fact, it’s just the application of Industrial evolutions goals to the supply chain. Let’s trace how supply chain evolution worked in conjunction with industrial evolution.

- Industry 1.0 focused on transforming the execution of the manufacturing processes. Thus, Supply Chain 1.0 focussed on the efficient utilization of available resources.

- Industry 2.0 moved towards mass production, sophisticated machinery, etc. to deliver higher products. Hence, Supply Chain 2.0 worked towards organizing processes to achieve higher productivity.

- Industry 3.0 started in the computer era so, Supply Chain 3.0 concentrated on incorporating automation.

- Today’s Supply 4.0 is running in hand with advanced technology-driven Industry 4.0 characteristics. This is with the aim of achieving higher process efficiency and a seamless flow of information across the supply chain.

On the other hand, Supply Chain 5.0 is a step ahead. It aims to meet the targets of all stages of the industrial revolution, within a balanced human-technological environment. It doesn’t aim to replace humans with machines but instead makes them work together in perfect synergies. So are you ready for this transition?

The essence of Supply Chain 4.0

Supply Chain 4.0 has been a key motivator in driving digitalization, globally. But not all the industries or markets have adopted its features in their supply chains. To brush up on our knowledge and understanding, let’s have a look at a few pointers that have the essence of Supply Chain 4.0.

Advanced technology-driven supply chain

Supply chain 4.0 much like Industry 4.0 marks the adoption of highly advanced technology-driven solutions at all stages of the supply chain. Smart sensing technologies like IoT, RFID, GSM, etc. were adopted for tracking & tracing vehicles and shipments, both in warehouses and on the go. The supply chains became more effective & resilient with the help of cognitive technologies like Artificial Intelligence(AI) and Machine Learning (ML). Other technologies like Big Data, blockchain, digital twins, etc. gathered & analyzed the right information, and provided the proper visibility to optimize the processes and make timely corrective decisions.

Integrated Supply Chain Ecosystems

Supply chains traditionally were pretty basic and straightforward. That means they worked on one-way communication from the supplier to production to distribution and finally,to the customer. Today they are a complex, close-knit, interconnected network of stakeholders. So, to keep everyone on the same page, they require multi-directional communication. Supply chain 4.0 creates the perfect flow of real-time communication along with intuitive reports and analytics for better functioning of the supply chains.

Dynamic communication

To accommodate the effects of changing supply and demand scenarios, supply chains have now become more flexible. Today’s automated supply chain software analyzes the on-ground situation and performs predictive analytics to ensure more responsiveness & agility in the processes. For example, the inventory management software analyzes the stock situation and predicts the upcoming demand to place orders for replenishment. The latest, ultra-modern manufacturing equipment is capable of sending production capacity feedback in real time.

Moving toward Supply Chain 5.0

Supply chain 5.0 is everything in Supply Chain 4.0, with an additional motive to achieve individualization & mass customization of the supply chains. Hence, to excel in the era, one needs to level up the three parameters mentioned above, with an increased focus on human-centricity. This stage of Industry 5.0 emphasizes getting the best of the human brain & technological capabilities. This is with the idea to incorporate more intelligence into the supply chain processes. Highly skilled professionals will be needed to work with intelligent systems & machinery and bring in increased supply chain efficiency.

New & even more advanced technologies need to be adapted to meet the requirements of Industry 5.0. These include collaborative robots (cobots), multi-agent systems and technologies, digital ecosystems, complex adaptative systems, 4D printing, 5D printing, 3D scanning, holography, intelligent autonomous systems, and machine cognition.

Additionally, sustainable development will be the main aspect of supply chain management, at this stage. There will be a greater emphasis on waste management, minimization of carbon emissions, and environment-friendly manufacturing processes.

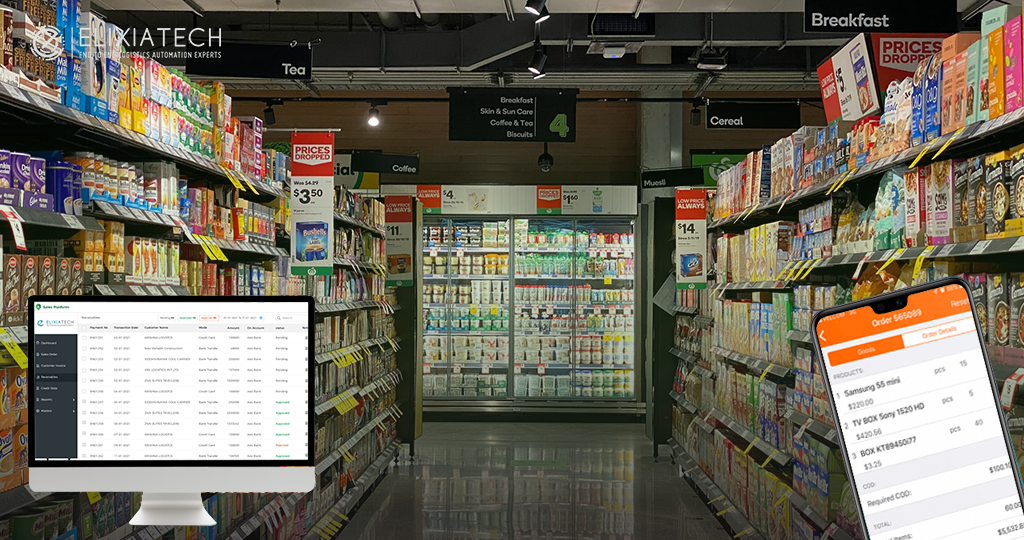

We, at Elixia, are committed to offering technologically progressive solutions to bring end-to-end supply chain visibility. To manage supply chain planning and execution, we provide interlinked soft bots for logistics, warehouse, and inventory. This helps in reducing costs for goods-in-transit and gaining actionable business intelligence. Our industry-agnostic, intelligent delivery solutions are suitable to all logistics segments and help improve operational efficiency and save on logistics costs.

Request for a call back now: https://elixia.tech/#requestacallback